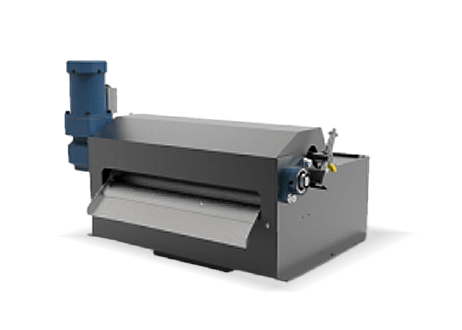

The drilling and tapping machine is a high-precision CNC machine tool that integrates drilling, tapping, and milling functions. It is designed to meet the high-efficiency and precision machining needs of industries such as automotive, aerospace, electronics, mold making, and home appliances. Its core advantage lies in completing multiple processes in a single setup, significantly shortening the production cycle and improving machining efficiency and quality.

We can provide CNC drilling and tapping machine with the model of GLD-T600 and GLD-T700 for you to choose

Simple adjustment of high-precision tapping stroke.

The double safety clutch device can prevent the breakage of the wire-tapping.

The cooperation of multi-axis tapping machines can produce high-efficiency operation.

It can be matched with a 2-24-axis movable multi-axis, fixed multi-axis, and indexing plate to improve production capacity and save time and effort.

According to the needs and options of customers' parts processing, we can plan, design and manufacture semi-automatic and automatic drilling and tapping machine cutting machines.

Mature numerical control system (Fanuc, Siemens, and YS-S800): The high-speed drilling and tapping machine is equipped with a system with high performance, high stability, and high-speed data processing capability, which is more effective in the three-dimensional processing process.

High-rigidity Spindle: The high-speed drilling and tapping machine features a powerful spindle with a maximum speed of 20,000 rpm and 7.5KW power, enabling efficient rigid machining. It utilizes high-precision bearings with low heat generation and low noise. The tool feed automatically and precisely synchronizes with the pitch during operation, without tool deflection.

| # | Standar | Option |

|---|---|---|

| 1 | Safety Door | Optical Linear Scale |

| 2 | Automatic Lubrication System | Chip Conveyor System |

| 3 | Fully Enclosure Guard | Tool Breakage Probe |

| 4 | Rigid Tapping | Oil Skimmer |

| 5 | Heat Exchange for Electric Cabinet | Oil Mist Collector |

| 6 | Coolant Tank & Chip Tray | Workpiece& Tool Probe |

| 7 | Dual LED Work Light | CTS |

| 8 | LED 3 Color Warning Light | Rotary Table |

| 9 | Spindle Oil Cooler | |

| 10 | Spindle Nose Air Blow | |

| 11 | Leweling Bolits and Pads | |

| 12 | M30 Auto Off |

First of all, the stroke of traditional drilling and tapping machines is generally within 800 × 400. Although it can be boring and milling, the milling load is weak, and it is generally used for drilling and tapping aluminum materials.

The high-speed drilling and tapping machine is continuously innovated on the basis of the traditional drilling and tapping machine. While developing the milling strength and the rigidity of the whole machine, the original processing efficiency of the drilling and tapping machine is maintained.Secondly, the high-speed profile drilling and tapping machine can be developed and customized according to the needs of different users. Compared with the traditional drilling and tapping machine, it can meet the different processing needs of different processing plants.Further advantages are listed below:

The high-speed drilling and tapping machine integrates the punching and tapping actions of the parts to be tapped, and the tapping and punching are directly performed on the punching machine simultaneously and improving the degree of automation and reducing the processing procedures.

The design of the high-speed drilling and tapping machine is sturdy and durable, small in size, and easy to install in different molds, and the tooth heads can be replaced with different specifications.

The use of high-speed drilling and tapping machines can save working time, with high tapping precision, short time, and high productivity.

We can also provide a one-stop solution service for your machine tool components.

English

French

German

Portuguese

Spanish